Delving into the world of aluminum siding installation cost sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset.

As we navigate through the complexities of factors influencing costs, average cost breakdowns, cost-saving tips, and comparisons with other siding materials, a comprehensive view emerges on the financial aspects of aluminum siding installation.

Factors Affecting Aluminum Siding Installation Cost

When it comes to determining the cost of installing aluminum siding, several key factors come into play. These factors can significantly influence the overall price of the project, making it essential to understand how each element contributes to the final cost.

Size of the Project

The size of the project is a crucial factor in determining the cost of aluminum siding installation. Larger projects typically require more materials and labor, resulting in higher overall costs. For example, a small single-story home will cost less to side than a large two-story house with multiple gables and angles.

Quality of Materials

The quality of materials used for aluminum siding can also impact the installation cost. Higher-quality materials may come at a higher price point but can offer better durability and aesthetics in the long run. Choosing premium materials may increase the initial cost but can save money on maintenance and repairs in the future.

Labor Costs

Labor costs play a significant role in the overall installation cost of aluminum siding. Skilled laborers with experience in siding installation may charge higher rates for their expertise. Additionally, factors such as the complexity of the project and the time required for completion can influence labor costs.

Location

The location of the project can also affect the cost of aluminum siding installation. Areas with higher costs of living or where labor is in high demand may have higher overall project costs. Additionally, factors like accessibility and local building codes can impact the pricing of the installation.

Additional Services

Additional services, such as the removal of old siding or the need for custom trim work, can add to the overall installation cost. These extra services require additional time, labor, and materials, which can increase the total price of the project.

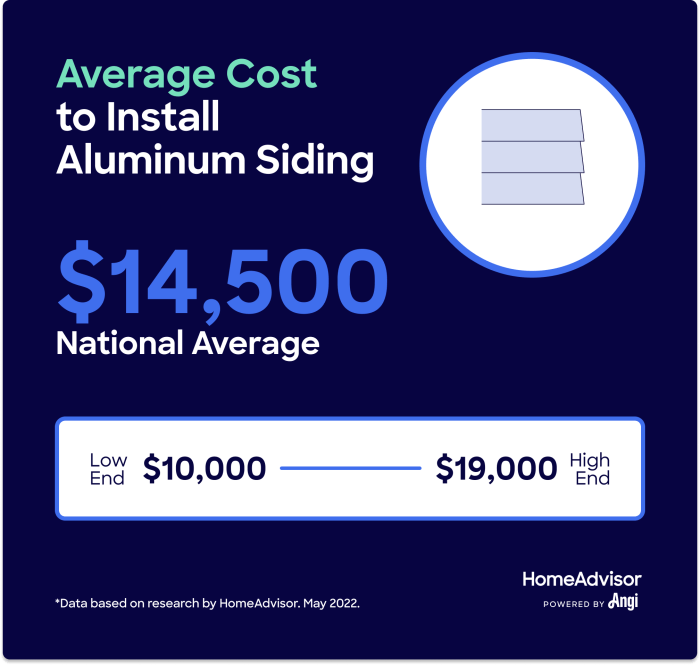

Average Cost Breakdown for Aluminum Siding Installation

When it comes to installing aluminum siding, understanding the average cost breakdown can help you budget effectively for the project. Let's delve into the various costs involved in aluminum siding installation to give you a clearer picture of what to expect.

Materials

- Aluminum siding panels: The cost of the siding panels can vary based on the quality and thickness of the material. On average, expect to pay between $2 to $4 per square foot for aluminum siding panels.

- Trim and accessories: Additional materials such as trim pieces, corner posts, and soffits will also add to the overall cost. Budget around $1 to $2 per linear foot for these accessories.

Labor

- Installation labor: The labor cost for installing aluminum siding will depend on the size of your home and the complexity of the project. On average, labor costs can range from $3 to $7 per square foot.

- Removal of old siding: If you have existing siding that needs to be removed before installing aluminum siding, this will incur additional labor costs. Plan for an extra $1 to $2 per square foot for the removal process.

Permits and Other Expenses

- Permit fees: Depending on your location, you may need to obtain permits for the siding installation. Permit fees can vary but typically range from $100 to $500.

- Equipment rental: In some cases, specialized equipment may be required for the installation process, leading to additional rental costs.

- Additional services: Factors such as the need for insulation, moisture barriers, or custom work can increase the overall cost of aluminum siding installation.

Cost-saving Tips for Aluminum Siding Installation

When considering aluminum siding installation, homeowners can implement various strategies to save money and reduce overall costs. These cost-saving tips range from DIY installation to negotiating labor costs and investing in high-quality materials for long-term benefits.

DIY Installation

One of the most effective ways to save money on aluminum siding installation is by opting for a do-it-yourself approach. By taking on the installation process yourself, you can eliminate labor costs and only need to invest in materials. However, it's important to have the necessary skills and tools to ensure a successful installation.

Bulk Material Purchasing

Another cost-saving tip is to purchase aluminum siding materials in bulk. Buying materials in larger quantities often comes with discounts or lower prices per unit. This can help homeowners save money on the overall cost of materials, especially for larger projects.

Negotiating Labor Costs

When hiring professionals for aluminum siding installation, homeowners can try to negotiate labor costs to lower the overall expenses. Discussing the scope of work, timeline, and any possible discounts with contractors can help in reducing labor costs without compromising on quality.

Investing in High-Quality Materials

While high-quality materials may have a higher upfront cost, they can lead to long-term cost savings. Durable and premium aluminum siding materials are less likely to require frequent maintenance or replacements, reducing future expenses on repairs and replacements. Investing in quality materials can also enhance the overall value and curb appeal of the property.

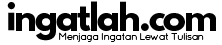

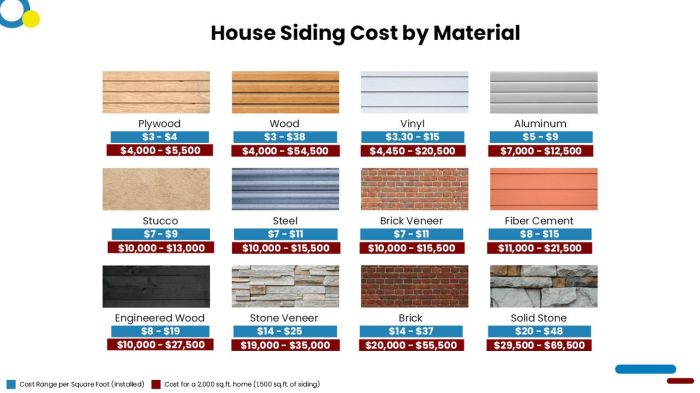

Comparing Aluminum Siding Installation Costs to Other Siding Materials

When considering siding options for your home, it's important to compare the installation costs of aluminum siding with other popular materials like vinyl, wood, or fiber cement. Each type of siding has its own set of cost factors that can impact your overall budget and long-term expenses.

Vinyl Siding

One of the most popular siding materials, vinyl siding is known for its affordability. The material cost for vinyl siding is generally lower than aluminum, making it a budget-friendly option for many homeowners. However, vinyl siding may require more frequent maintenance and replacement compared to aluminum, which could increase long-term costs.

Wood Siding

Wood siding is often chosen for its natural aesthetic appeal and durability. While the initial material cost of wood siding can be higher than aluminum, the installation costs may vary depending on the complexity of the project. Wood siding requires regular maintenance, such as painting or staining, which can add to the overall expenses over time.

Fiber Cement Siding

Fiber cement siding is a durable and low-maintenance option that offers a similar look to wood siding. The material cost of fiber cement siding falls between aluminum and wood, making it a mid-range option for homeowners. While the installation costs for fiber cement siding may be comparable to aluminum, the longevity and minimal upkeep required can make it a cost-effective choice in the long run.

Closing Summary

In conclusion, the journey through aluminum siding installation costs reveals a nuanced understanding of the intricacies involved in this process. From identifying key factors to exploring cost breakdowns and examining cost-saving strategies, homeowners are equipped with valuable insights to make informed decisions for their siding projects.

Key Questions Answered

What factors influence aluminum siding installation cost?

Factors like project size, material quality, labor costs, location, and additional services can all impact the overall installation cost.

How can homeowners save money on aluminum siding installation?

Homeowners can save money by considering DIY installation, bulk material purchasing, and negotiating labor costs. Investing in high-quality materials can also yield long-term cost benefits.

How does the cost of aluminum siding installation compare to other siding materials?

Compared to materials like vinyl, wood, and fiber cement, aluminum siding may offer cost-effectiveness in the long run due to differences in installation costs, maintenance, and longevity.